This walkthough explains how to return to base settings (factory settings) on your 21BB engine.

The HPI 21BB engine has got a three needle carburetor with a high speed, a mid-range, and a low speed needle.

Therefore bringing the low speed needle to it's base setting is slightly different from a two needle carburetor.

In this walk through we will show you the differences between adjusting the 21BB engine and adjusting the S-25 as shown in great detail on the HPI RC cars DVD.

For your 21BB engine we recommend watching the getting started S-25 video on the HPI RC cars DVD and reading this walkthrough in addition.

There are also two video clips at the end of this page showing how to adjust the 21BB engine.

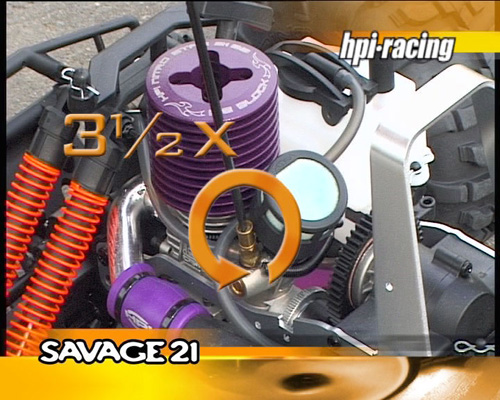

We start with the high speed needle.

Turn the needle clockwise until it is closed. This shuts off all fuel supply, then open three and a half turns anticlockwise, this is the base setting for the high speed needle.

In most cases the high end needle is the only one which needs adjustment. So if you have problems always try resetting this high end needle to the base setting first.

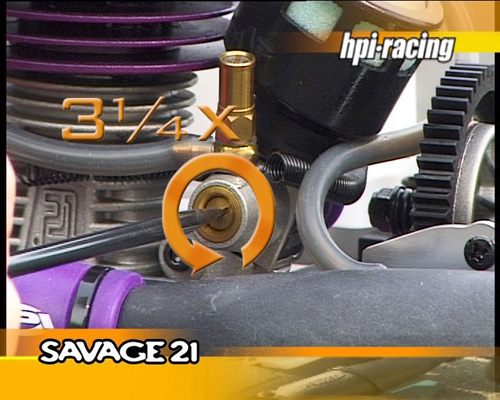

Now turn the midrange needle clockwise until it is closed.

From closed, open three and a quarter turns, this is the base setting for the mid-range needle.

To return the low speed needle to its base settings you have to hold the mid-range needle with a screw driver to prevent it from being turned.

Then cerfully turn the low speed needle clockwise until you can feel it is turning the midrange needle. Be carefull not to loose the base settings of the midrange needle.

Then, still holding the mid-range needle, open the low-speed needle 3 and a half turns. This is the base setting of the low speed needle.

You will use this base setting for breaking in the engine and as a starting point for the tuning process or fault finding.

[strong]Tuning the 21BB[/strong]

To adjust your HPI 21BB engine follow the same procedure as with the S25 or T-15 engine. This is shown in great detail on the HPI RC Cars DVD.

From base settings, start adjusting the high speed needle in 1/8 of a turn.

Then adjust the low speed needle in 1/8 of a turn.

Keep in mind: Never run the engine too lean, as this can damage the engine.

The mid-range needle does not need to be adjusted. Always run it at base settings.